Gas Flow Detection

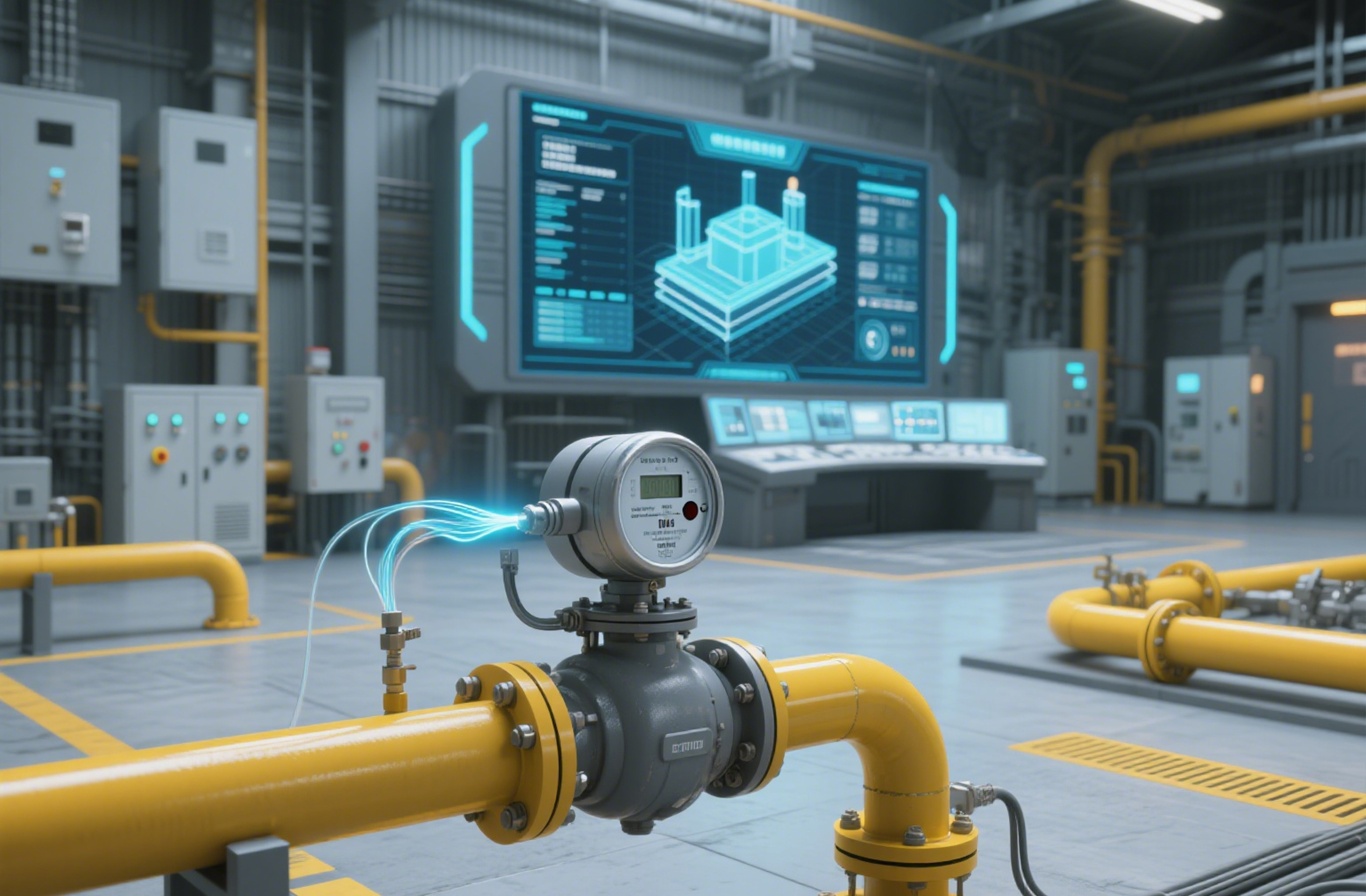

Ultrasonic Gas Flow Transducer: Precision Measurement for Gaseous Fluids

Gas Flow Detection

The ultrasonic gas flow transducer is a state-of-the-art device used to measure the flow rate of gases in pipelines, industrial systems, and environmental applications. By utilizing ultrasonic sound waves, this technology provides high-precision, non-invasive flow measurements, making it an essential tool in industries such as natural gas, petrochemical, HVAC, and environmental monitoring.

The principle behind ultrasonic gas flow measurement is based on time-of-flight technology or the Doppler effect. In time-of-flight systems, ultrasonic waves are sent through the gas, and the time it takes for the sound waves to travel between sensors is measured. Changes in the gas flow velocity affect the travel time of these waves, which are then analyzed to calculate the flow rate. This method ensures accurate, real-time data with minimal disruption to the system.

Key Advantages:

-

High Accuracy – Ultrasonic technology ensures precise measurement of gas flow, even in challenging conditions, providing reliable data for both high and low-flow rates.

-

Non-Invasive Measurement – There are no moving parts in ultrasonic gas flow transducers, which eliminates the need for pipe modifications and results in minimal maintenance and longer device lifespans.

-

Wide Measurement Range – Capable of measuring a broad range of gas flow rates, from very low to very high flows, making it suitable for various industrial applications.

-

Durability – Designed to withstand harsh environmental conditions, including extreme temperatures, pressures, and corrosive gases, ensuring long-term reliability.

-

Real-Time Data – Provides instant, continuous feedback on gas flow, enabling operators to make timely adjustments and optimize system performance.

-

Low Maintenance – With no moving parts, ultrasonic transducers require minimal maintenance compared to mechanical flow meters, lowering operational costs.

-

Compact and Lightweight – Ultrasonic gas flow transducers are compact and easy to install, offering an ideal solution for both new installations and retrofits.

How It Works:

-

Ultrasonic Wave Emission – The transducer emits high-frequency ultrasonic sound waves into the gas stream within a pipeline or duct.

-

Wave Interaction – As the gas moves through the pipe, the velocity of the flow affects the time it takes for the sound waves to travel from one sensor to another.

-

Data Calculation – The system calculates the difference in travel time or Doppler shift, translating this into a precise measurement of the gas flow rate.

-

Real-Time Output – The flow data is immediately displayed or transmitted to control systems, offering continuous monitoring of gas flow conditions.

Applications:

-

Natural Gas Industry – Used for accurate flow measurement in pipelines transporting natural gas, ensuring effective distribution and monitoring of gas usage.

-

Petrochemical and Chemical Plants – Monitors the flow of gases involved in chemical processing and manufacturing, helping to optimize processes and reduce waste.

-

HVAC Systems – In heating, ventilation, and air conditioning (HVAC) systems, ultrasonic gas flow transducers measure air and gas flow for efficient system performance and energy savings.

-

Energy and Power Generation – Used in power plants to monitor the flow of gases such as steam, air, and combustion gases, ensuring optimal performance of turbines, boilers, and other equipment.

-

Environmental Monitoring – Used in industrial facilities to track emissions and ensure compliance with environmental regulations, ensuring safe and eco-friendly operations.

-

Medical and Laboratory – For accurate measurement of gases in laboratory setups, medical gas systems, and other research applications.

-

Food and Beverage Industry – In production lines that involve gaseous phases, such as carbonation in beverages, ultrasonic transducers provide accurate flow measurement for quality control.

Why Choose Ultrasonic Gas Flow Transducers?

-

Accuracy – Ultrasonic gas flow transducers offer high-precision flow measurement with minimal error, even in fluctuating flow conditions.

-

Non-Invasive and Low Maintenance – With no moving parts, these sensors provide a maintenance-free solution, reducing long-term costs and downtime.

-

Energy Efficiency – By optimizing gas flow in industrial systems, ultrasonic flow transducers help improve energy efficiency and minimize operational costs.

-

Adaptability – Suitable for various gas types and flow conditions, including corrosive, non-corrosive, and hazardous gases, making them adaptable across industries.

-

Real-Time Monitoring – The transducers provide continuous, real-time data, enabling operators to make informed decisions quickly and efficiently.

-

Cost-Effective – The non-invasive nature and minimal maintenance requirements result in a lower total cost of ownership compared to traditional mechanical flow meters.

Optimizing Gas Flow Measurement with Ultrasonic Technology

HTW's ultrasonic gas flow transducers deliver reliable, accurate, and non-invasive measurement solutions for all types of gas flow applications. Whether monitoring natural gas, air, or other gaseous substances, these transducers provide real-time feedback and unmatched precision. Their robust design and minimal maintenance requirements make them the ideal choice for industries that demand both reliability and efficiency in their flow measurement systems.

By choosing HTW ultrasonic gas flow transducers, you ensure accurate data, increased system efficiency, and long-term savings for your operations.

Related Products

Product Inquiry

Leave the information you want to consult, we will contact you as soon as possible