Level Detection

Nothing

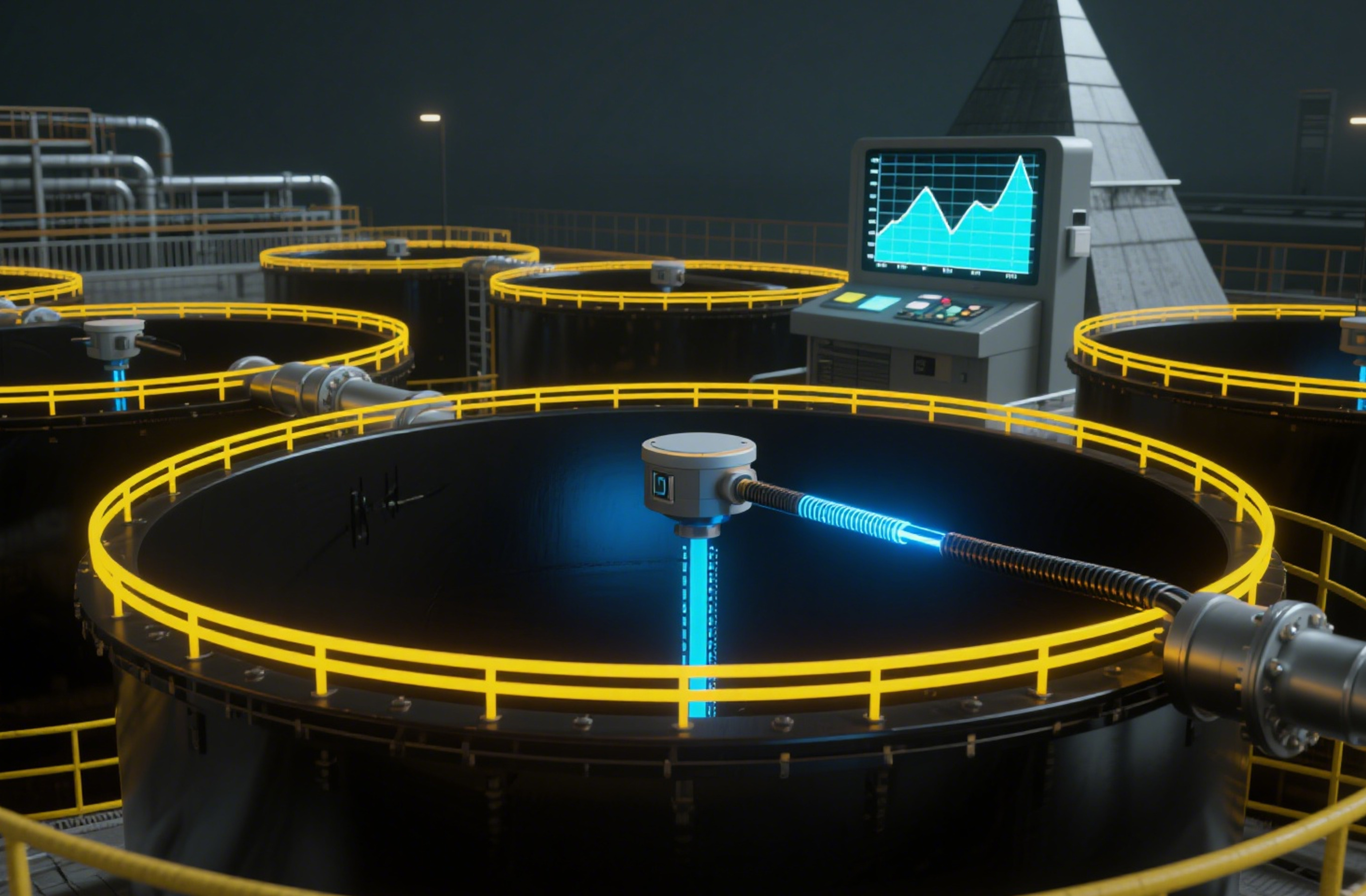

Ultrasonic Level Detection – Precision, Reliability, and Non-Contact Measurement

Ultrasonic level detection is a non-contact measurement technology used to determine the level of liquids or solids within a container, tank, or open environment. It operates based on the time-of-flight (ToF) principle: an ultrasonic transducer emits a high-frequency sound pulse toward the surface of the target material. The pulse reflects back from the surface, and the sensor calculates the distance based on the time it takes for the echo to return.

This measured distance is then used to determine the material level, making the system ideal for applications where cleanliness, reliability, and maintenance-free operation are critical.

🔹 Key Advantages

-

Non-Invasive Measurement

Ultrasonic sensors do not require physical contact with the measured medium, making them ideal for corrosive, hazardous, viscous, or sterile environments. -

Broad Material Compatibility

Works with a wide range of substances, including clear or opaque liquids, slurries, granules, and powders. Unlike optical or capacitive sensors, ultrasonic sensors are unaffected by color, transparency, or reflectivity. -

High Accuracy and Repeatability

Offers stable, real-time measurements with millimeter-level resolution across a wide range of distances. Advanced signal processing algorithms minimize false readings due to turbulence, vapor, or foam. -

Low Maintenance

With no moving parts, ultrasonic level sensors are highly durable, wear-resistant, and require minimal maintenance compared to mechanical floats or contact-based methods. -

Flexible Mounting and Integration

Sensors can be top-mounted, side-mounted, or even externally attached to a container wall in specialized configurations. Output options include analog (e.g., 4–20 mA, 0–10 V), digital (e.g., UART, I²C, RS485), or switch-based triggers for alarms and process control.

🔹 Typical Applications

-

Industrial Process Control

Monitoring liquid or bulk material levels in tanks, silos, and hoppers across chemical, pharmaceutical, and food industries. -

Water and Wastewater Management

Used in storage tanks, wells, pump stations, and sewer systems for level control, overflow protection, and pump automation. -

Smart Home and Appliance Integration

Integrated into washing machines, humidifiers, and water dispensers for automated fluid management. -

Agriculture and Livestock Systems

Monitoring levels of feed, grain, or fertilizer in silos and containers. -

Medical and Laboratory Equipment

Enables precise fluid level sensing in diagnostic and therapeutic devices where hygiene and accuracy are essential.

🔹 HTW’s Ultrasonic Level Detection Solutions

At HTW, we offer a range of custom-engineered ultrasonic level detection transducers and sensor modules, backed by our in-house development of high-performance piezoelectric ceramics. Our solutions are designed for integration flexibility, high sensitivity, and application-specific durability, ensuring reliable performance in even the most demanding environments.

Related Products

Product Inquiry

Leave the information you want to consult, we will contact you as soon as possible